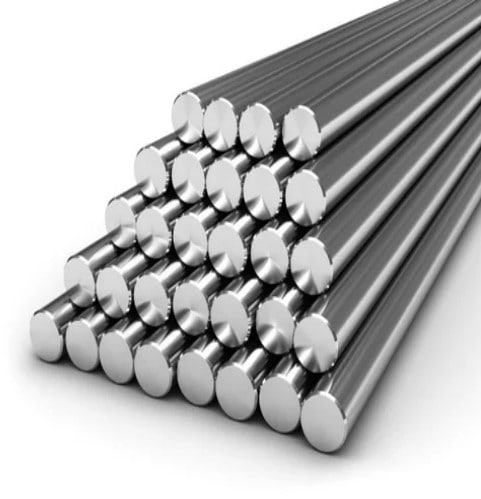

304 Stainless Steel | 304L Stanless Steel

UNS S30400 | UNS S30403304 Stainless Steel | 304L Stainless Steel

304 stainless steel—originally known as 18-8 stainless steel due to its nominal composition of 18% chromium and 8% nickel—is one of the most widely used and readily available grades of austenitic stainless steel in the world. Its popularity is driven by an excellent balance of corrosion resistance, mechanical properties, ease of fabrication, and cost effectiveness. Closely related is 304L stainless steel, a low-carbon version of 304 that is often dual certified to meet both specifications, making it especially useful in welded applications.

Composition and Metallurgical Characteristics

304 stainless steel is classified as an austenitic stainless steel, meaning it has a face-centered cubic crystal structure. This structure gives 304 its characteristic toughness, ductility, and non-magnetic properties in the annealed condition. The chromium content provides corrosion resistance by forming a passive oxide layer on the surface, while nickel stabilizes the austenitic structure and enhances formability.

304L stainless steel differs primarily in its lower carbon content, typically limited to a maximum of 0.03%. This reduction in carbon significantly decreases the risk of carbide precipitation during welding or exposure to elevated temperatures. As a result, 304L offers improved resistance to intergranular corrosion without the need for post-weld heat treatment.

Because modern production methods allow mills to meet both chemistry and mechanical requirements, many products are dual certified as 304/304L, allowing them to be used interchangeably in most applications.

Corrosion Resistance and Performance

Both 304 and 304L stainless steel provide excellent resistance to corrosion in a wide range of environments, including atmospheric exposure, freshwater, and many chemical processes. They perform particularly well against oxidation and most organic and inorganic acids. However, they are not typically recommended for chloride-rich environments, such as marine applications, where pitting or crevice corrosion may occur.

These grades maintain good mechanical properties across a broad temperature range. They perform well at cryogenic temperatures, retaining toughness and impact resistance, and they also offer good oxidation resistance at elevated temperatures, making them suitable for heat-related applications.

Fabrication and Weldability

One of the key advantages of 304 stainless steel is its exceptional ease of fabrication. It can be readily formed, machined, rolled, and drawn into complex shapes. Both 304 and 304L are easily welded using standard welding techniques. The low carbon content of 304L makes it the preferred choice for heavy sections or extensively welded components, as it minimizes the risk of weld decay.

These grades also respond well to polishing and finishing, which is especially important in sanitary and aesthetic applications.

Common Industries and Applications

Due to their versatility, 304 and 304L stainless steels are used across a broad range of industries:

- Aerospace: Structural components, fasteners, and fittings where corrosion resistance and reliability are critical.

- Chemical Processing: Tanks, piping, heat exchangers, and vessels handling mildly corrosive chemicals.

- Food and Beverage Processing: Equipment, conveyors, storage tanks, and processing lines that require excellent cleanliness, corrosion resistance, and ease of sanitation.

- Oil and Gas: Piping, valves, and pressure-containing components used in non-chloride environments.

- Sanitary and Cryogenic Applications: Medical equipment, pharmaceutical processing systems, and low-temperature storage vessels.

- Pressure-Containing Applications: Pressure vessels, fittings, and components requiring strength and corrosion resistance under load.

Available Product Forms

304 and 304L stainless steels are available in a wide range of product forms, making them suitable for virtually any manufacturing or construction need. Common forms include:

- Round bar, hex bar, square bar, rectangle and flat bar

- Plate and sheet

- Hollow bar

- Tubing and pipe

- Forgings

This extensive availability allows engineers and designers to select the optimal form for their specific application without compromising material performance.

Conclusion

304 stainless steel and its low-carbon counterpart, 304L stainless steel, remain foundational materials across countless industries. Their combination of corrosion resistance, mechanical strength, fabrication ease, and wide product availability makes them a dependable and cost-effective solution for everything from food processing equipment to pressure-containing systems. With dual-certified 304/304L material now widely available, users can confidently specify these grades knowing they will perform reliably in both welded and non-welded applications for years to come.

Standards

- UNS S30400

- UNS S30403

Characteristics

- Excellent resistance to corrosion.

- Good fabrication and formability

- Good cryogenic strength and toughness

Physical Properties

- Density: 0.285LB/in³ (7.90g/cm³)

- Melting Point: 2550–2590°F (1398–1421°C)

- Modulus of Elasticity: 29.0x10⁶psi (200 GPa)

- Magnetic Permeability: 1.02 Max @ 200 H (Annealed)

Chemical Composition

C

Mn

S

P

Si

Cr

Ni

Mo

* 304L stainless steel has a Ni range of 8.0–12. 0, but to be dual certified material must be within range of 304 stainless steel.

Mechanical Properties

Mechanical properties can be altered (increased/decreased) by many methods such as cold working or strain hardening, or by the addition or modification of chemistry. Grades such as 304L Condition B are strain hardened, while grades like 304LNi, or 304H are grades with altered chemistry. However, these grades are more specialized and may not be available in all forms and sizes.

KSI (MPa)

KSI (MPa)

HRC (BHN)

Specialty Steel Supply makes all reasonable efforts to ensure the accuracy and correctness of the data found on this website and the associated documents but makes no representations or warranties as to the data’s accuracy, correctness or reliability. All data are for general information only and not for providing design advice. It is the responsibility of the user to test specific alloys under actual service conditions to determine their suitability for a particular purpose.

Stainless and Alloys

We collaborate to help you exceed requirements by bringing your best ideas forward and eliminating non-conformance.

Specialty Steel Supply Inc. is one of the largest distributors of austenitic, precipitation hardened, duplex and martensitic stainless steels. We have a wide range of products and types of stainless steel round bar and our well trained staff offers many years of experience in all aspects of the steel industry. Our ability to procure and source metals from all parts of the world allows us to stay competitive in a global marketplace. We are committed to developing and servicing just in time inventory programs.

Specialty Steel Supply

19201 Circle Lake Drive

Pinehurst, Texas 77362

info@specialtysteelsupply.com

Business Hours

Sunday - Closed