303 Stainless Steel

UNS S30300303 Stainless Steel

303 stainless steel is one of the most widely used grades of stainless steel for applications that demand extensive machining. Known as a free-machining stainless steel, it offers significantly improved machinability compared to other common 300-series stainless steels such as 304L and 316L. This unique balance of corrosion resistance, workability, and consistency has made 303 stainless steel a preferred choice across many industries where precision and efficiency are critical.

What Is 303 Stainless Steel?

303 stainless steel is an austenitic stainless steel alloy primarily composed of iron, chromium, and nickel, with the intentional addition of sulfur. The sulfur content is what sets 303 apart from other 300-series grades. This addition enhances machinability by improving chip breaking during cutting operations, reducing friction, and minimizing tool wear.

Because of this characteristic, 303 stainless steel machines faster and more smoothly, and cutting tools typically last longer when working with it. This makes it an excellent choice for high-volume production environments or parts requiring tight tolerances and detailed machining.

Like other austenitic stainless steels, 303 cannot be hardened through heat treatment. Strength can only be increased through cold working processes such as drawing or rolling.

Machinability Advantages

The defining feature of 303 stainless steel is its superior machinability. Compared to 304L or 316L, manufacturers often experience:

- Faster machining speeds

- Improved surface finishes

- Reduced tool wear and replacement costs

- Better chip control during turning, milling, and drilling

These benefits translate directly into lower production costs and higher throughput, making 303 stainless steel especially popular in screw machine and CNC machining operations.

Corrosion Resistance

303 stainless steel offers good corrosion resistance in mild to moderately corrosive environments. It performs well against atmospheric corrosion, fresh water exposure, and many chemicals. However, due to its sulfur content, its corrosion resistance is slightly lower than that of 304 or 316 stainless steel.

For this reason, 303 is best suited for applications where excellent machinability is more important than maximum corrosion resistance. It is not typically recommended for highly corrosive environments such as marine or chloride-rich conditions.

Mechanical Properties and Performance

As an austenitic alloy, 303 stainless steel maintains good ductility and toughness, even at low temperatures. It also offers good formability and weldability, though welding can be more challenging than with 304 stainless due to sulfur content, which can increase the risk of hot cracking.

Key characteristics include:

- Non-magnetic in the annealed condition

- Excellent polishability for cosmetic or sanitary components

- Consistent mechanical performance across production runs

These attributes make 303 stainless steel ideal for components that require machining, grinding, or polishing without sacrificing structural reliability.

Common Applications and Industries

Thanks to its machinability and versatility, 303 stainless steel is used across a wide range of industries. Typical applications include:

- Aerospace: Precision fasteners, fittings, and machined components

- Screw Machine Production Parts: High-volume turned parts such as shafts, pins, and bushings

- Valve and Pump Components: Bodies, stems, and internal fittings

- Fittings and Connectors: Threaded components requiring dimensional accuracy

- Medical and Pharmaceutical Equipment: Non-implant components, housings, and fasteners

- Pulp and Paper Processing: Machined parts exposed to mild corrosive conditions

- General Industrial Applications: Hardware, couplings, and precision mechanical parts

In each of these industries, the combination of corrosion resistance and ease of machining makes 303 stainless steel a cost-effective and reliable material choice.

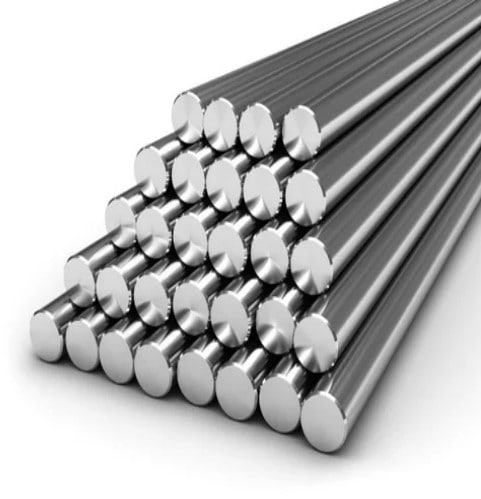

Available Product Forms

303 stainless steel is available in a wide variety of product forms to meet diverse manufacturing needs, including:

- Round bar

- Hex and square bar

- Rectangular and flat bar

- Plate and sheet

- Hollow bar

- Tubing and pipe

- Forgings

This broad availability allows engineers and fabricators to source the material in the most efficient form for their specific application, minimizing waste and machining time.

Summary

303 stainless steel stands out as a free-machining stainless steel designed for efficiency, precision, and consistency. While it may not offer the highest corrosion resistance in the 300-series family, its exceptional machinability, good mechanical properties, and wide product availability make it an excellent choice for machined components across numerous industries.

For manufacturers focused on productivity, tooling longevity, and high-quality finishes, 303 stainless steel remains one of the most practical and dependable stainless steel options available today.

Standards

- UNS S30300

Characteristics

- Excellent machinability compared to 304 or 316L whilst maintaining the strength and corrosion resistance.

Physical Properties

- Density: 0.285LB/in³ (7.90g/cm³)

- Melting Point: 2550–2590°F (1398–1421°C)

- Modulus of Elasticity: 28.0x10⁶psi (193 GPa)

- Magnetic Permeability: 1.008 Max @ 200 H (Annealed)

Chemical Composition

C

Mn

S

P

Si

Cr

Ni

Mo

Mechanical Properties

Mechanical properties can be altered (increased/decreased) by the addition of other chemical elements like Selenium (Se) to form 303Se. However, these grades are more specialized and may not be available in all forms and sizes.

KSI (MPa)

KSI (MPa)

HRB (BHN)

Specialty Steel Supply makes all reasonable efforts to ensure the accuracy and correctness of the data found on this website and the associated documents but makes no representations or warranties as to the data’s accuracy, correctness or reliability. All data are for general information only and not for providing design advice. It is the responsibility of the user to test specific alloys under actual service conditions to determine their suitability for a particular purpose.

Stainless and Alloys

We collaborate to help you exceed requirements by bringing your best ideas forward and eliminating non-conformance.

Specialty Steel Supply Inc. is one of the largest distributors of austenitic, precipitation hardened, duplex and martensitic stainless steels. We have a wide range of products and types of stainless steel round bar and our well trained staff offers many years of experience in all aspects of the steel industry. Our ability to procure and source metals from all parts of the world allows us to stay competitive in a global marketplace. We are committed to developing and servicing just in time inventory programs.

Specialty Steel Supply

19201 Circle Lake Drive

Pinehurst, Texas 77362

info@specialtysteelsupply.com

Business Hours

Sunday - Closed